- Reaction score

- 0

Hi,

I have been trying to solve this problem for months now. I work as an Electrical Engineer in a tunnel project, we will use TBM machine to drill the underground station.

We just realized that for the new TBM machine that we bought, we actually have 2 tanks of grout component, called component A. The problem is, we are using the panel for old TBM machine where the component A tank only have one.

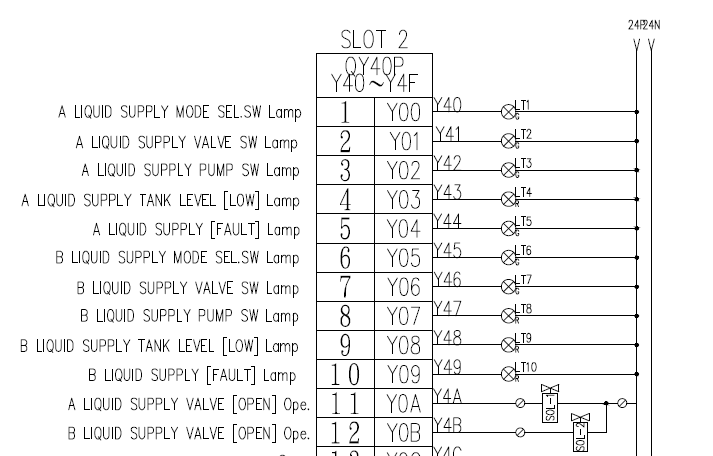

So, in order to provide additional control for the second tank to the existing control for the first tank, I am planning to modify a little bit of the control circuit where, from the level sensor in the tank, it will send signal to the PLC in the panel. This PLC will send command for the valve to open, and hence will make the pump runs.

We do not intend to modify any coding in PLC since it was done by a subcontractor. What we can do is only mechanical modifications, where my boss gave an idea to use a simple relay. He asked me to crack down on how to implement it, maybe using 4 poles relay, but until now I still can't figure it out.

I was trying to implement the simple basic start and stop pushbutton circuit, where I try to manipulate the start and stop pushbutton by changing it to high and low signal from the level sensor, but the problem on how to connect them to PLC still cannot be solved, since we need to integrate two signals from two level sensors into one slot of PLC, and from one slot of output PLC to command either two valves to open.

I have been trying to solve this problem for months now. I work as an Electrical Engineer in a tunnel project, we will use TBM machine to drill the underground station.

We just realized that for the new TBM machine that we bought, we actually have 2 tanks of grout component, called component A. The problem is, we are using the panel for old TBM machine where the component A tank only have one.

So, in order to provide additional control for the second tank to the existing control for the first tank, I am planning to modify a little bit of the control circuit where, from the level sensor in the tank, it will send signal to the PLC in the panel. This PLC will send command for the valve to open, and hence will make the pump runs.

We do not intend to modify any coding in PLC since it was done by a subcontractor. What we can do is only mechanical modifications, where my boss gave an idea to use a simple relay. He asked me to crack down on how to implement it, maybe using 4 poles relay, but until now I still can't figure it out.

I was trying to implement the simple basic start and stop pushbutton circuit, where I try to manipulate the start and stop pushbutton by changing it to high and low signal from the level sensor, but the problem on how to connect them to PLC still cannot be solved, since we need to integrate two signals from two level sensors into one slot of PLC, and from one slot of output PLC to command either two valves to open.