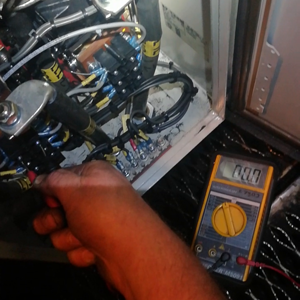

OK I've got 2 contactors where the coils are wired in parallel.

They are sitting right next to each other,

One pulls in and holds perfectly well. The other pulls in and drops out. Pulls in again drops out. Ect. Ect. For as long as you are trying to keep the contacts closed.

I've tried swapping out contactors, I've tried swapping the wiring around,

Same thing.

This is an established system that's been working fine for probably as long as I've been alive.

Any clues on what to try.

Cheers

They are sitting right next to each other,

One pulls in and holds perfectly well. The other pulls in and drops out. Pulls in again drops out. Ect. Ect. For as long as you are trying to keep the contacts closed.

I've tried swapping out contactors, I've tried swapping the wiring around,

Same thing.

This is an established system that's been working fine for probably as long as I've been alive.

Any clues on what to try.

Cheers