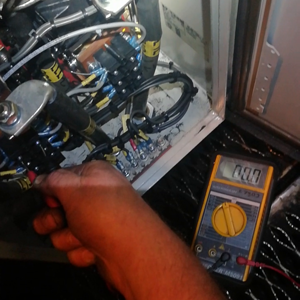

hmmmnz: I have asked Albright to send me the datasheet for your contactor. Watching your two videos we can see the voltage dip down to 50V in one clip and 60V in the other.

The force of a solenoid is:

F = (n x i)2 x magnetic constant x a / (2 x g2)

where n is number of turn, a is area and g is length of air gap. So, the force is proportional to the current squared or to the applied voltage squared if the coil resistance R is constant.

What this means is the the relationship is parabolic:

where y is force F and x is current I.

So, the force produced by the solenoid(S1/S2 coil) increases more rapidly as the magnitude of the current/voltage increases; or the force decreases more rapidly as the magnitude of the current/voltage decreases. The effect then is if the coil of the contactor S1/S2 is first energised with a low voltage the pull in force will be lower than at a higher voltage - the contacts may not then close with sufficient force to make a good enough conduction region for the starting current. Some arcing will occur tending to push the contacts apart which reduces the starting current a little and at the same time increases the applied voltage to the coil - the contacts are then pulled together with a slightly greater force. The starting current increases once again but the contacts are not made well enough so there is some more arcing tending to push them apart. This 'hunting' continues until the start current has dropped to a sufficient level that the contact pressure can pass this current without arcing.

The long and the short of it is I wonder if the problem is not S2 per se but the out of specification drop in applied supply voltage because:

1. The 110V battery is not fully charged.

2. The battery has aged so its internal resistance has increased limiting its ability to provide high current without excess volt drop.

3. There are some high current supply (+ and -) conductors which have poor connections including on the battery.

4. The starter motors have faults or are struggling to start the diesel for some reason.

Quite why the problem only occurs for S2 I suggest (don't know) is because of some magnetic interaction between S1, S2 and the magnetic fields around the high current conductors which tends to promote the hunting effect for S2 but not/not as much for S1. Or the polarity matters in the sense it can reduce or aggravate hunting.

Can you charge up the 110V battery to see if it has an effect on the problem?

[automerge]1572605355[/automerge]

I have to go out now but here is what I have from Albright:

Type:

SW200A-33

Coil Voltage (V) 72 INT DC

Coil Resistance (Ohms) 167

Pull In Voltage (V) 50.0 Maximum

Drop Out Voltage (V) 16.0 Maximum

Coil Power Dissipation (W) 31.04

Additional Features

RED ADHESIVE DOT POSITIONED ON FRONT OF TOP COVER , SAME SIDE AS

3-WAY TERMINAL BLOCK - SEE DRAWING 2155-113.

SPECIAL LABEL FITTED STATING COIL RESISTANCE, SEE DRAWING 2155-113.

SOCKET SET 2BA GRUB SCREWS MUST BE USED TO LOCK AUXILIARY PLUNGER.

All figures above are stated at 20 degrees Celsius