-

Please checkout the new poll we will be pushing hard, and want some good stories to come out of this

result are public - you can change your vote over time, which might genuinely be the case from time to time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss About Stepper Motors in the UK Electrical Forum area at ElectriciansForums.net

_q12x_

DIY

- Reaction score

- 212

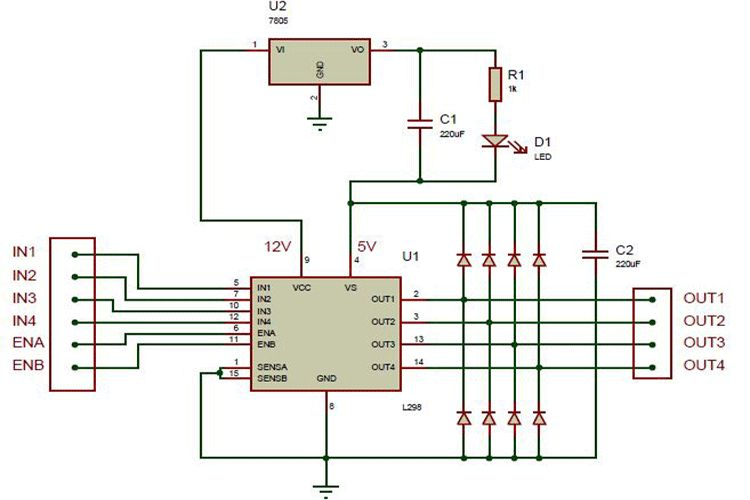

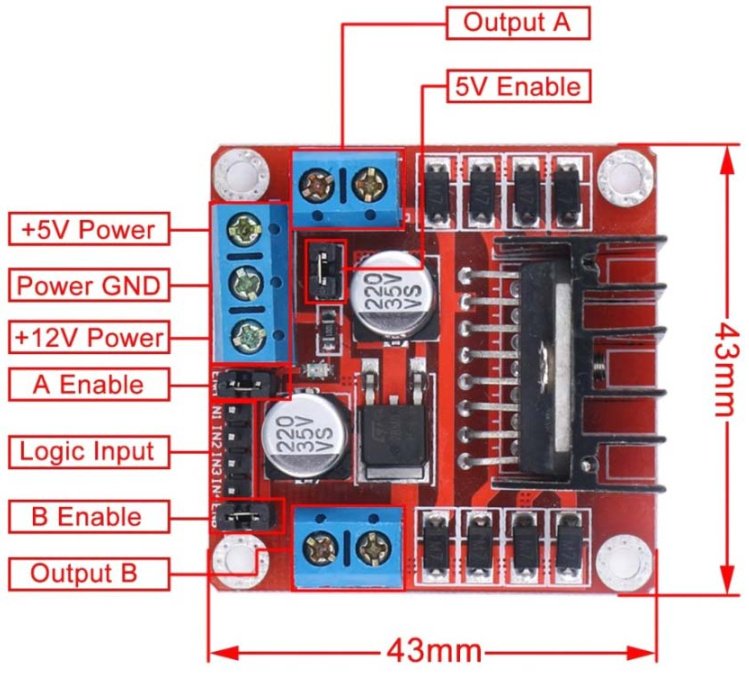

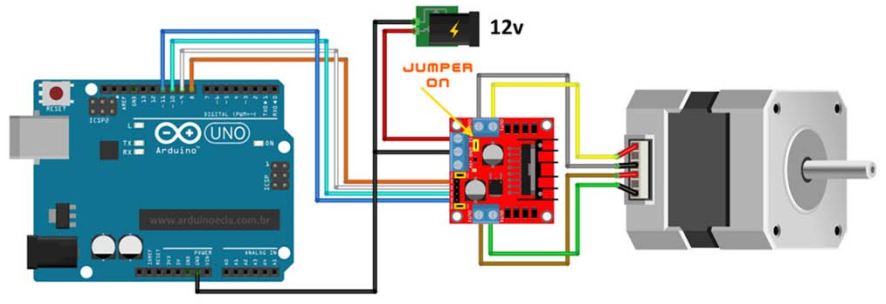

I was just demystifying L298N Motor Driver Module for 4 wires cct right now. It turns out it is having only a fixed 7805 VReg at 5V @500mA and 2 filter capacitors, one for the variable Input and another for the constant 5V output.

I also find this cct online, that is the exact same cct from this module datasheet, but is much more clear to me:

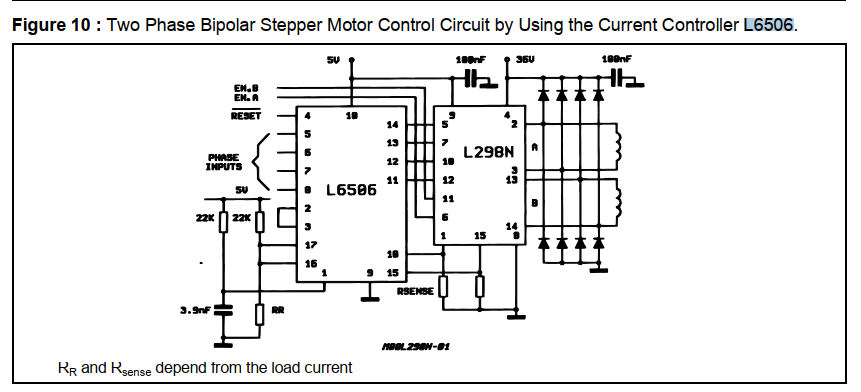

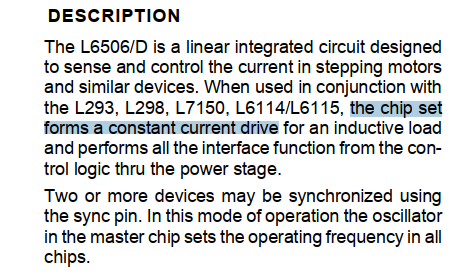

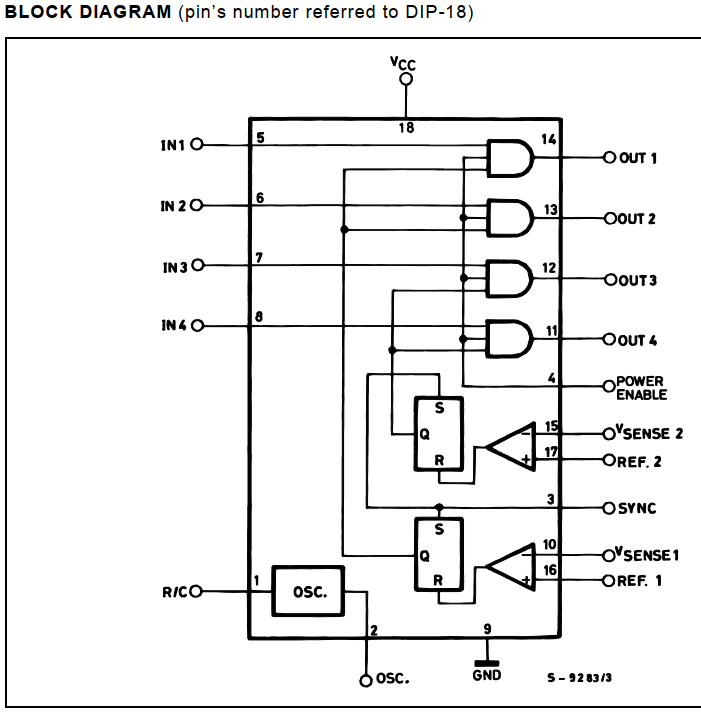

Then, I was also paying attention to the recommended current controller IC L6506 recommended to be used with L298 . It is a new chip for me, and I really have no idea what really does... although I read its datasheet, Im still loking stupid at it.

...further in time...

- I believe I may understand the practical reason for this L6506 IC. I believe, it is using some sort of feedback from the motor and it is --maintaining-- the same speed and torque of the motor, by automatically regulating the current.

The text selection I made is telling me what --might-- be. And I think I'm right.

- I strongly believe it is pretty much like my lathe, when I apply force on the motor spindle, when Im cutting into metal, the speed and force is maintained and not decreased as long as I press into the axe.

The simple way....

I believe...(I dont know for sure) the simplest way of driving this L298 IC is to use an arduino.

The complicated way...

Is using this L6506 IC internal cct logic. Since I dont have the chip and no one told me about it to take it in time. I didn't look very hard either in the datasheet as well.

Ive already read the entire description of this L6506 chip and I decided is a very cool function to have with my stepper motors.

I believe is a moderately 'simple' logic circuit to build. I looked at the prices already for the L6506 IC and is a bit expensive for the moment. I will live without it for awhile, and build myself its internal logic cct.

I also find this cct online, that is the exact same cct from this module datasheet, but is much more clear to me:

Then, I was also paying attention to the recommended current controller IC L6506 recommended to be used with L298 . It is a new chip for me, and I really have no idea what really does... although I read its datasheet, Im still loking stupid at it.

...further in time...

- I believe I may understand the practical reason for this L6506 IC. I believe, it is using some sort of feedback from the motor and it is --maintaining-- the same speed and torque of the motor, by automatically regulating the current.

The text selection I made is telling me what --might-- be. And I think I'm right.

- I strongly believe it is pretty much like my lathe, when I apply force on the motor spindle, when Im cutting into metal, the speed and force is maintained and not decreased as long as I press into the axe.

The simple way....

I believe...(I dont know for sure) the simplest way of driving this L298 IC is to use an arduino.

The complicated way...

Is using this L6506 IC internal cct logic. Since I dont have the chip and no one told me about it to take it in time. I didn't look very hard either in the datasheet as well.

Ive already read the entire description of this L6506 chip and I decided is a very cool function to have with my stepper motors.

I believe is a moderately 'simple' logic circuit to build. I looked at the prices already for the L6506 IC and is a bit expensive for the moment. I will live without it for awhile, and build myself its internal logic cct.

- I think is best to do the simple way first, to get it running and familiarize with the L298 chip itself. And after that, add this new layer of cool but more complicated cct. That's the plan. Wish me luck.

- Any helpful comments are welcome. My first time with this L298 chip. Very virgin right now. Haha.

Last edited:

- Reaction score

- 4,348

Hello. Editing while my wife shops

The first thing to think about is how to provide a 35V Vcc supply of say 2 to 3 A dc for the 298 driver. Whereas the H bridge driver circuits were constant voltage drivers and the current through the coils rose and decayed as in a series resistor inductor circuit in response to an on and off voltage waveform, the 298 cleverly uses a higher voltage to increase the initial rate of rise of current through the coils which enables the stepper to operate at faster rotation rate with less reduction of torque as speed increases. The other chip has two external resistors placed in series with the two coils to sense the current through them. When the sensed voltage exceeds a threshold voltage the second chip knows the coil current I is greater than Iy the desired current through the coil and it tells the 289 to turn off the energising voltage Vx to the stepper coil. When current decays - the inductance of the coil will act to try and maintain current flow - and I is less then Iy, the threshold voltage is sensed as low and the chip turn on Vy again. For each coil, the energising voltage is being turned on and off - 'chopped' - but because of the coil's inductance the current is maintained largely constant. See my electrical art which was scribbled in the shop while I was waiting and is largely right. Obviously the full Vcc voltage across the coil would cause too much current to flow for too long and is likely to cause overheating. But the chopped waveform and the sensing of the coil current means that the average current is not greater than the specified maximum current for the coil. This quick explanation tells you why the chip is a constant current driver.

The first thing to think about is how to provide a 35V Vcc supply of say 2 to 3 A dc for the 298 driver. Whereas the H bridge driver circuits were constant voltage drivers and the current through the coils rose and decayed as in a series resistor inductor circuit in response to an on and off voltage waveform, the 298 cleverly uses a higher voltage to increase the initial rate of rise of current through the coils which enables the stepper to operate at faster rotation rate with less reduction of torque as speed increases. The other chip has two external resistors placed in series with the two coils to sense the current through them. When the sensed voltage exceeds a threshold voltage the second chip knows the coil current I is greater than Iy the desired current through the coil and it tells the 289 to turn off the energising voltage Vx to the stepper coil. When current decays - the inductance of the coil will act to try and maintain current flow - and I is less then Iy, the threshold voltage is sensed as low and the chip turn on Vy again. For each coil, the energising voltage is being turned on and off - 'chopped' - but because of the coil's inductance the current is maintained largely constant. See my electrical art which was scribbled in the shop while I was waiting and is largely right. Obviously the full Vcc voltage across the coil would cause too much current to flow for too long and is likely to cause overheating. But the chopped waveform and the sensing of the coil current means that the average current is not greater than the specified maximum current for the coil. This quick explanation tells you why the chip is a constant current driver.

Attachments

Last edited:

- Reaction score

- 4,348

Good morning. Just watched your progress report video. Two comments if I may?

1. Put a heat sink on the L289N;

2. The L289N will not operate the best it can in voltage drive mode as you have it now because the voltage is too low and the current flowing is too high for too long so it overheats. You need to control it using the L6506 so that using the voltage chopping technique inside the 6506 the 289 will drive the coils of the stepper motor with constant current albeit the value of this constant current can be varied by varying threshold voltages values at which the higher voltage motor supply is turned on and off ie chopped.

Here is a clearer diagram of chopped voltage waveform and resulting coil current waveform than my earlier electrical art - but not too dissimilar than my drawing I think you will agree

:

:

Image credit: Oriental Motor USA Corp.

Last edited:

_q12x_

DIY

- Reaction score

- 212

It is Under-Powered/Voltage. No need at this testing stage. I was aiming for its safe zone of operation.1. Put a heat sink on the L289N;

And I find it to be at 3.3V. Over that, will heat up. But also depends on the motor used as well. For the scrapped motor will be a bit higher, 4V running cold.

Not correct. It is Under-Powered Under-Voltage. It is as I tell you, running cold a these safe values. What you dont know is that the voltage and current are proportional. Meaning, as long as I increase the voltage, the current will increase as well. And vice-versa(but I don't have this capability). I tested at 3.3V and 4V for about 10minutes and all this time, run cold. No current too high as you say.2. The L289N will not operate the best it can in voltage drive mode as you have it now because the voltage is too low and the current flowing is too high for too long so it overheats.

Heating occurs over a certain voltage but everything remains constant beyond 10 seconds of running.

Yah... thats the next thing in plan. I do not have this chip and it adds too much to my budget expenses. And also will be used sporadically. So my plan is to actually make it's internal cct that consists of 2 opamps, a FF and a clock. Easy to make, but a bit spacey. I can live with that.You need to control it using the L6506

- Reaction score

- 4,348

I leave you with somethings to ponder - why does your current project spin the motor slowly and smoothly albeit in steps but when you increase the pulse rate it stops rotating? And you may notice that over the range the motor spins as the rotational speed rises the torque the motor is producing decreases - why?

_q12x_

DIY

- Reaction score

- 212

That is the nature of a stepper motor. The higher the frequency the smaller the torque. And vice-versa, the smaller the speed, the higher the torque. Is nothing to wonder about. Is like looking at the sky and ask me why the clouds are moving. Because thats the way sky works. The same as with the stepper. And the faster the fv applied to the coils, the faster it runs. But in a certain limit. After that limit, or certain fv, the stepper is unable to spin anymore, and losses its rithm. I already establish these limits.I leave you with somethings to ponder - why does your current project spin the motor slowly and smoothly albeit in steps but when you increase the pulse rate it stops rotating? And you may notice that over the range the motor spins as the rotational speed rises the torque the motor is producing decreases - why?

Reply to About Stepper Motors in the UK Electrical Forum area at ElectriciansForums.net

Similar Threads

hello guys i have a (3-6v dc motor), (DC Motor PWM Speed Controller 3V 6V 12V 24V 35V), (3.7v 1200mah rechargeable battery) and a (Charging /...

- Replies

- 4

- Views

- 647

This is more a challenge to myself and why not for some of you as well. I will try to make it myself alone but... it will be easier and faster...

- Replies

- 3

- Views

- 1K

Hi, I have a project I have been working on, that has me out of my depth with regard to my knowledge, as I am a very basic electronic hobbies...

- Replies

- 5

- Views

- 1K

Please advise what I should test / check next.

My usual qualified electrician who did all of the work here is in Ireland for 4 weeks and not...

- Replies

- 45

- Views

- 3K

Hello !

I am building for some time a cct to drive a 3digit multiplexed LCD. (from aliexpress)

From the sellers on aliexpress I managed to find...

- Replies

- 7

- Views

- 1K

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

YOUR Unread Posts

-

-

Class II fitting modified by ElectricianI find with these so called 'class 2' metal light fittings which are basically class 1 fittings...

- Latest: Welchyboy1

-

Solar Storm causing Northern Lights to glow! Show us your pics!I’ve stuck one on the good morning thread before I saw this one…. So here’s some more…

- Latest: littlespark

This website was designed, optimised and is hosted by untold.media Operating under the name Untold Media since 2001.