Unless I'm much mistaken , the current rating for Wiska boxes relates specifically to the supplied terminals not the boxes themselves. They play no part in the connections and as such have no current rating. I'm sure there could be an argument about potential temperatures with a high current circuit such as this... the boxes themselves have temperature ratings that typically exceed that of the cable itself along with a substantial voltage rating. They are more than capable of enclosing three 25mm butt crimps. If there is enough heat generated to damage the Wiska box, the cable will already be suffering damage and the insulation may already have failed.

You could argue that about any enclosure we use in a domestic setting, but if a householder chooses to use a tool and open an enclosure, they've made that choice. Someone accessing that box to read the meter has no choice... they have to do it for their job so we should make every effort to ensure it is as safe as it can be. Plus, I'll throw in there that the cables leaving the meter are the responsibility of the home owner. Within the meter cupboard they are perhaps the only thing that specifically has to comply with BS 7671 as if they are the home owners responsibility they fall within our remit, unlike the rest of the equipment/cabling in there. I've had a WPD guy flip his lid on me because I had the audacity to have 1 or 2mm of the single insulated core of the tails visible at the meter (not my doing, I didn't cut the meter seal but he wasn't happy and had me re-terminate it). Those are the reasons I think the advice you received from your CPS is bad.

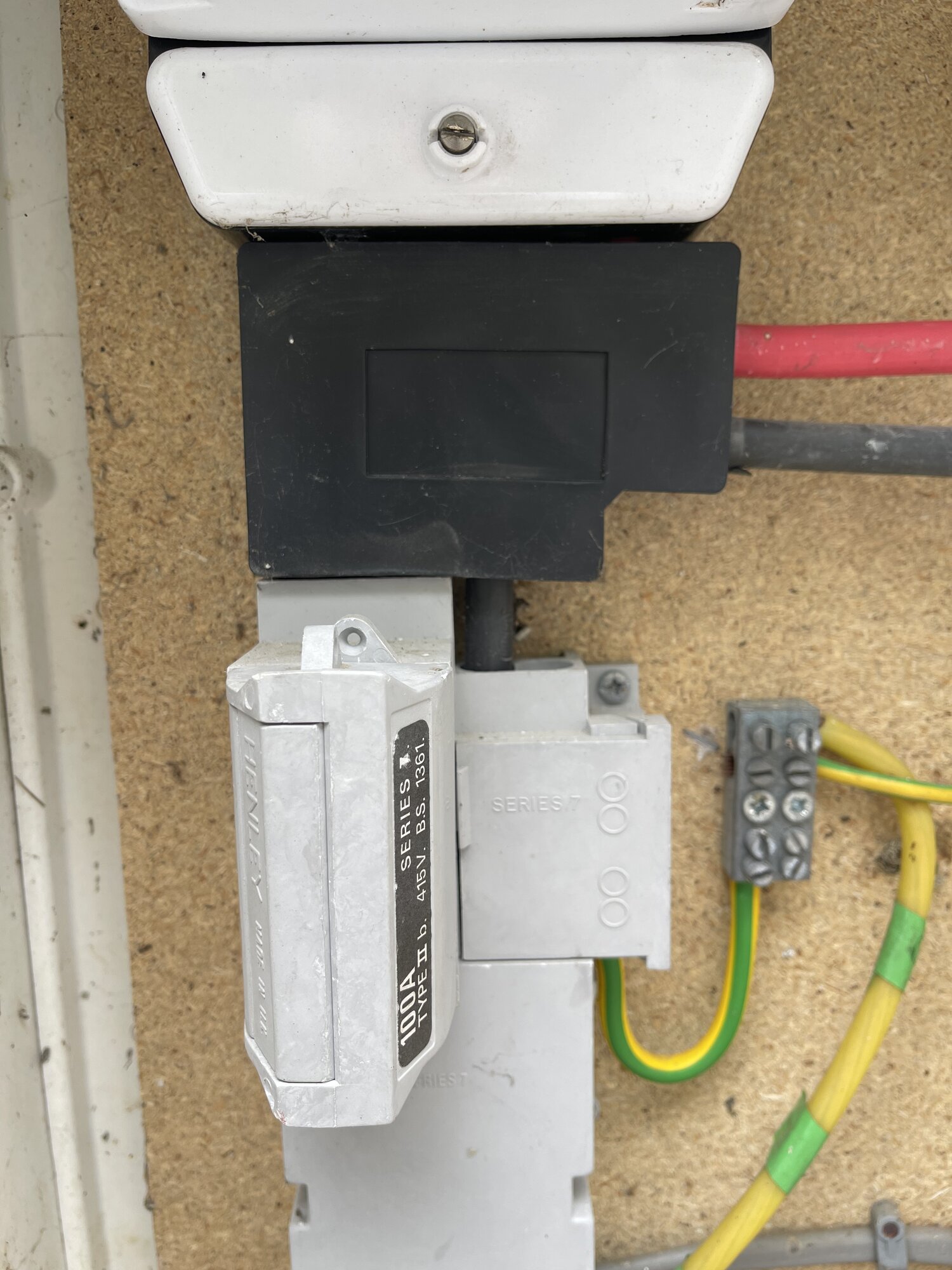

@pc1966 's suggestion of heatshrink is an excellent idea (possibly a couple of layers), or maybe even some flexible conduit into an adaptable box.

I'm not going to argue about the cable and the possibility of jointing it either under the box or even inside the property as I've not seen it, I was just commenting (as we all do here) making some suggestions. I will say this though, for me "straight into" doesn't imply a distance. It could be literally straight through the wall (as you state) or it could drop down a bit first... if it dropped down to the floor and went through the wall, I'd still say "it goes out of the box and straight into the house" meaning it doesn't go anywhere or connect to anything else.

If 'the extreme' is making the conscious effort to try and ensure everything we do complies with BS 7671, then I'm there for that. Sometimes, the extreme is the right thing to do and if the customer won't entertain that then I don't want to be working for them. We're the ones who have to sign to say it's safe and compliant with BS 7671, not the customer, who'll be the first person in the queue to sue you if something untoward happens.

If you're happy putting your name to it, that's fine, that's your choice. Personally I wouldn't be for the reasons I've outlined. If I was inspecting it, it would be a C2 for basic insulation visible outside an enclosure and as I've implied, if I was expected to do what you've done without being able to properly gland that cable I would never have taken the job on.