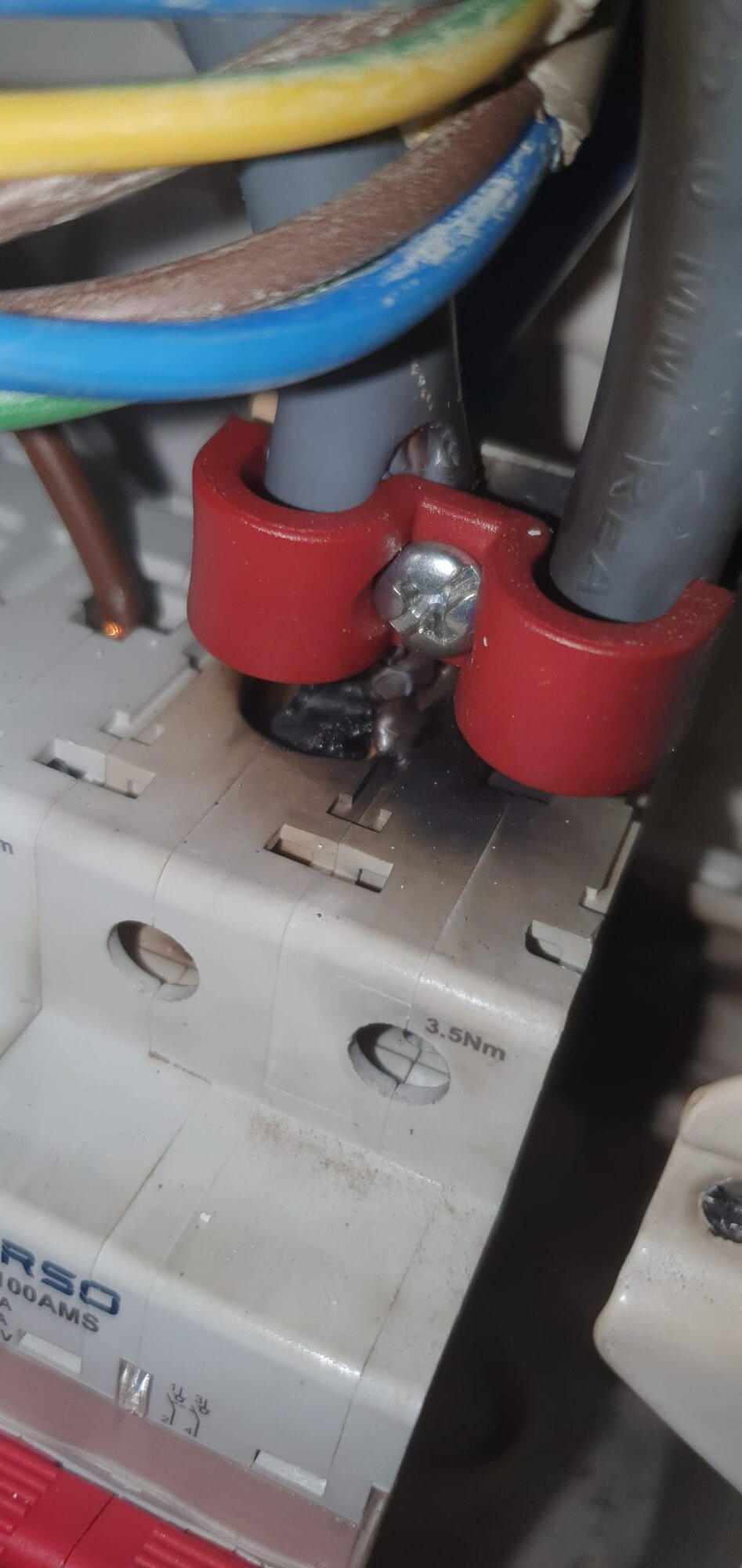

Perhaps should have mentioned it. You are looking for - what looks like a poor attempt at welding.. You should see black burn marks either at the back of the red clamp or black burn marks on the backplane, the melted - either copper or steel is plain to see in the pic.

Its no big deal, *hit happens, whoever repaired it will know the real reason.

If you have an overload that blows the doors off you may wish to consider the efficacy of your overload devices, lol

Anyway, you can hardly expect to be told that the electrician who disturbed the cable clamp and cable made a total *ollocks, i may admit to it, if it was me, depends on how i feel on the day.

Its possible it was previously fitted to an inch of its life and the EICR guy just fitted it back without "being fully alert"

(generous hat off)