-

Please checkout the new poll we will be pushing hard, and want some good stories to come out of this

result are public - you can change your vote over time, which might genuinely be the case from time to time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Search the forum,

Shortest route from A to B. Swing out under trunking lid. Notch conduit boxes. Just whatever gets the job done, tools packed up and on the road home at the earliest possible time.

Don't get me wrong; there are some good guys out there, but the good guys are few and far between. Most turn up on site swaggering like the fourth emergency service, suck air through their teeth and then turn out rougher work than most people would think possible.

Several large firms used to sub out installations and getting a good job entirely depended on whether the subbies had high personal standards and were willing to go the extra mile while getting paid a sub-optimal rate for it. A rare few did this regardless, but needless to say this was the exception not the rule. The install usually stayed appalling for the first year until the service team went out for first annual inspection and testing, had a hissy fit, and then one of us would get the call to go and "tidy it up a bit" which often meant doing most of it again much to the irritation of the boss of the service side.

My suggestions that it would be better to keep an eye on the original install fell of deaf ears, and I eventually moved to a much smaller firm, a period I look back on with fondness as the guys were brilliant, teamwork at its best, and high standards.

On a related theme, my mate just died who invented the throat lozenge. There was no coffin at his funeral.

Where they keep the horses.

@!*#. Damnit

Hearses.

I see them walk in to newly competed buildings, with almost everything done for them, and still leave the place in a mess. To be fair, fire alarm installers are still a few steps above the guys who do intruder alarms. They walk into the same new installation and start work on a spiders web.

If the copper pipe isn't connected to the fcu and isn't an extraneous conductive part and the cable is double insulated, then the pipe isn't an exposed conductive part and wouldn't require bonding.

But each to their own

It's like the old Meat Loaf song - 4 out of 8 ain't bad,

I charge the client a full days ££££

Fancy junction box.

Went to test the cabling left behind by one tenant when they vacated an office, only found 2 pairs connected but on some it was 12&45, others it was 36&78 (or something like that), but also with pairs swapped so 36&78 might appear on 12&45 on the other end. Plus a few where there was nothing connected according to the tester.

Story was that the previous tenant (also a client of ours) had several offices, when they left, they had their electrician separate the networks so each was separate. No offence intended, but like previous criticism of plumbers and alarm installers, "a few" electricians really shouldn't be let loose with network cabling - especially if they aren't prepared to invest in at least the most basic of test equipment.

So, anyone like to guess what was wrong ?

I think they've wired it in with the feeds, hence nicebutdim's comment.

Thise who've worked with network cabling for a while will know that the panels have different terminal layouts. This may or may not work ...

Some have the terminals like this :

45 12 36 78

Bl Or Gr Br

01

02

Bl Or Gr Br

45 12 36 78

i.e. all the terminals for port 1 are in a line on the top, with those for port 2 in a line at the bottom.

Some have tbe terminals like :

45 12 45 12

Bl Or Bl Or

1 2

Gr Br Gr Br

36 78 36 78

Needless to say, the clueless idiot didn't bother looking at the markings and used the wrong layout. So socket 1 had 2 pairs from port 1 and 2 pairs from port 2. Then socket 2 had the other 2 pairs from ports 1&2 ! And so it went, with the added bonus that none of the cables were numbered and he'd mixed a few of those up as well.

Basically had to pull all the cables off the panel, work out which was which (give the tone set an outing), and reterminate them.

On another occasion, the tenant took their cabinet and were supposed to leave the cabling. Something got lost in translation, as their lecky just chopped the bundle of cables - fortunately, leaving just enough length to re-use them (again, tone set job to work out which was which).

Bought my first RJ45 crimper back in the summer to make up half a dozen cables. All worked first time, except one 40m cable, so I invested in a cheap cable tester recommended in a thread on here. Soon found the problem using that. Master was sequencing 1,2,3...8, while the slave was sequencing 8,7,6...1 - I'd crimped one of the plugs on upside down. Could make out which is was through the translucent plastic of the plug, so five minutes later and one scrap plug, all was good.

I find this to be a decent tester for the price.

Also using through hole wiring plugs makes life easier

Yes. Much easier.

Unfortunately, wherever you put these sockets, it's going to be in the wrong place for someone - and sure enough, a business moved in but needed the internet connection to their server room the other side of the unit. So one 40m cable and a few lifted floor tiles later, internet provided where it was needed. Only it "didn't work".

We ended up on a 4 way call - me, the people who at the time managed the network for us, the customer's IT guy, and their external IT support. It turned out, the guy "knew" he needed a crossover cable so cut the plug off and fitted a new one wired as a crossover. - neither our switch, nor his firewall had auto MDI (most devices will automatically switch modes as needed these days so crossover cables are rarely needed, this was some time ago).

The customer's IT guy talked him through finding another crossover cable and an inline coupler. The customer said he'd found one and "it's yellow, is that OK ?" His IT guy responded as I'd have loved to ... "I don't f***in care what colour it is as long as it's crossover".

Needless to say, with the extra crossover in line, our "it's not working" service sprang into life. I managed to refrain from "I told you so" (or something to that effect).

They had to feel good standing back and looking at that upon completion.

Need to be careful with these. I chased down an issue at work recently where these had been used but a few hadn't been cut perfectly flush. Results in them not sitting square and breaks contact.

Also in damp environments they can occasionally get a bit fusty at the bare ends and again make poor contact.

In defence of the LV folk, i started in this trade - and there is an art to it - just like with mains. A caring LV installer will confirm that with enough practice and the right technique its possible to make a sound and easy crimp, first time with traditional RJ45s.

Plus it was easier than explaining all the other stuff I did - without giving away too many secrets.

Discuss Dodgy trade pictures for your amusement! - 1 Million Views! in the UK Electrical Forum area at ElectriciansForums.net

- Reaction score

- 4,659

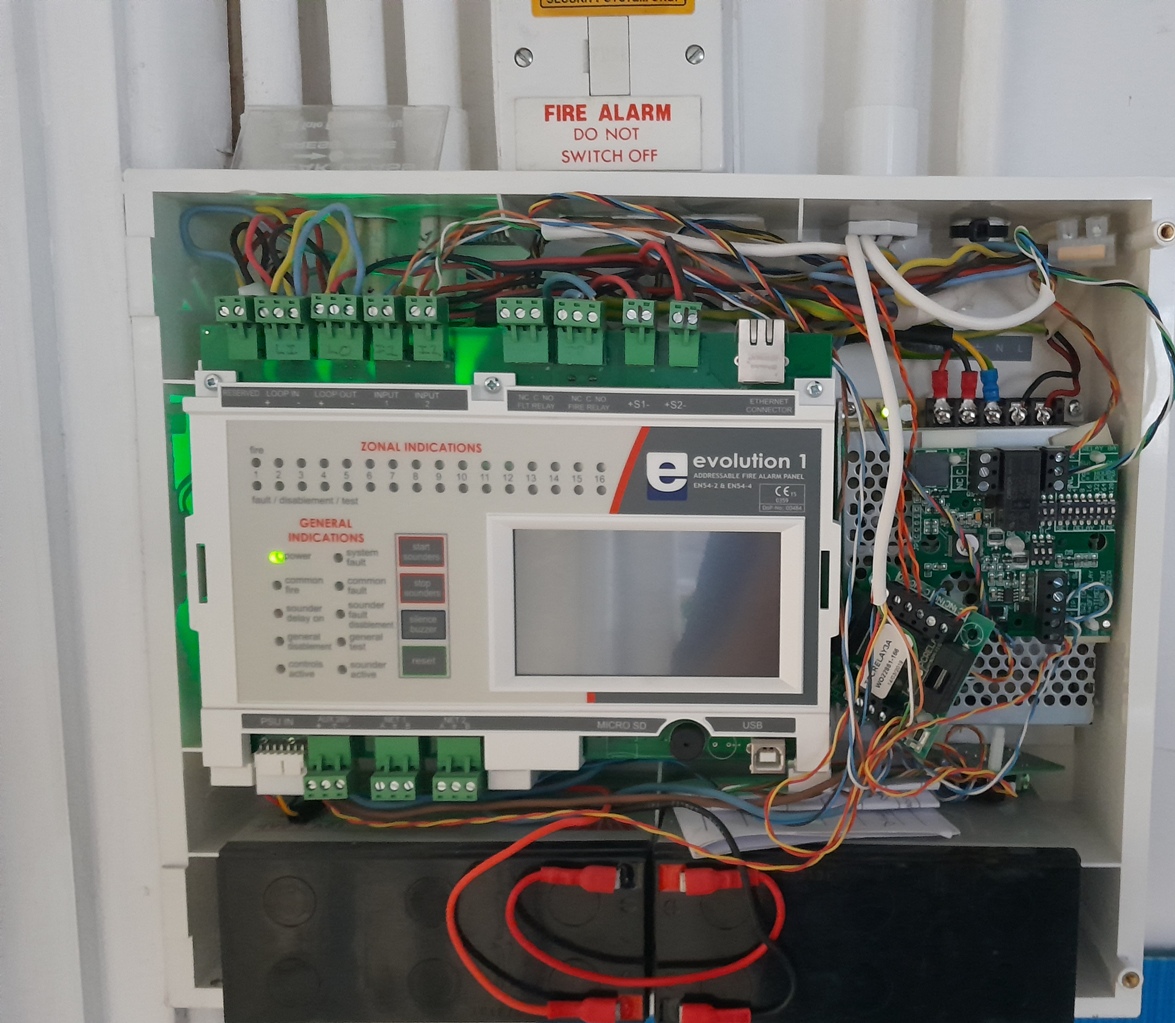

Fire alarm system, thank goodness I didn't have to work on it. only one conduit is bushed into the control panel, 3 have female adaptors but no bush, one is just poked in and has a cable tie around it. The less said about the dangling pcbs the better.

The conduit to the call point has no fixings other than the female adaptor in the top of the box.

The conduit to the call point has no fixings other than the female adaptor in the top of the box.

Last edited:

- Reaction score

- 6,893

The less said about fire alarm installers, the better.Fire alarm system, thank goodness I didn't have to work on it. only one conduit is bused into the control panel, 3 have female adaptors but no bush, one is just poked in and has a cable tie around it. The less said about the dangling pcbs the better. View attachment 110786

The conduit to the call point has no fixings other than the female adaptor in the top of the box.

View attachment 110787

Shortest route from A to B. Swing out under trunking lid. Notch conduit boxes. Just whatever gets the job done, tools packed up and on the road home at the earliest possible time.

Don't get me wrong; there are some good guys out there, but the good guys are few and far between. Most turn up on site swaggering like the fourth emergency service, suck air through their teeth and then turn out rougher work than most people would think possible.

- Reaction score

- 4,380

You forgot, hand on chin and slow head shake from side to side, tends to happen with all trades though.The less said about fire alarm installers, the better.

Most turn up on site swaggering like the fourth emergency service, suck air through their teeth and then turn out rougher work than most people would think possible.

- Reaction score

- 6,893

Hands on hips for fire alarm installers.You forgot, hand on chin and slow head shake from side to side, tends to happen with all trades though.

- Reaction score

- 8,933

I used to be work in this area and I agree! Though I did more fault finding and rectification than installing.The less said about fire alarm installers, the better.

Several large firms used to sub out installations and getting a good job entirely depended on whether the subbies had high personal standards and were willing to go the extra mile while getting paid a sub-optimal rate for it. A rare few did this regardless, but needless to say this was the exception not the rule. The install usually stayed appalling for the first year until the service team went out for first annual inspection and testing, had a hissy fit, and then one of us would get the call to go and "tidy it up a bit" which often meant doing most of it again much to the irritation of the boss of the service side.

My suggestions that it would be better to keep an eye on the original install fell of deaf ears, and I eventually moved to a much smaller firm, a period I look back on with fondness as the guys were brilliant, teamwork at its best, and high standards.

- Reaction score

- 17,150

I just had experience of this yesterday.

Was on my ongoing job at a funeral directors where they’ve built a second mortuary inside the garbage they keep the cars in.

There was a smaller room there before, used for coffin storage, and had a smoke detector in it.

Alarm engineer came, disconnected the detector base, pulled out the cable back to the call point and put the EOL in the call point.

Now the new room has been built, although a little bigger floor area and height, the same engineer turns up to “put the detector back on”

He spent over an hour on the phone to his boss asking if this room actually needed a detector or not…. admitted to me that he didn’t really know the regulations…. And seemed to me like he was swerving the job.

10 to 12m of FP200, a handful of P clips and the old base and detector…

To my mind it’s just as much risk as a storage room. More electrical devices, chemicals… staff will be working in there for some time, not just in and out.

“Oh, it’s an install job now.” teeth sucking noises

You could have had it done the time you’ve been on that bloody phone.

Was on my ongoing job at a funeral directors where they’ve built a second mortuary inside the garbage they keep the cars in.

There was a smaller room there before, used for coffin storage, and had a smoke detector in it.

Alarm engineer came, disconnected the detector base, pulled out the cable back to the call point and put the EOL in the call point.

Now the new room has been built, although a little bigger floor area and height, the same engineer turns up to “put the detector back on”

He spent over an hour on the phone to his boss asking if this room actually needed a detector or not…. admitted to me that he didn’t really know the regulations…. And seemed to me like he was swerving the job.

10 to 12m of FP200, a handful of P clips and the old base and detector…

To my mind it’s just as much risk as a storage room. More electrical devices, chemicals… staff will be working in there for some time, not just in and out.

“Oh, it’s an install job now.” teeth sucking noises

You could have had it done the time you’ve been on that bloody phone.

- Reaction score

- 16,729

But i was assuming the box was attached to the cpc.

do you think there is a need to bond the pipe, assuming the cable comes into the box double insulated?

Personally i was thinking if the flex was secured inside the back box with a cable clamp then the tube need not be bonded, if it is free to move then i think the tube should be bonded.

but I am open to peoples suggestions.

I just had experience of this yesterday.

Was on my ongoing job at a funeral directors where they’ve built a second mortuary inside the garbage they keep the cars in.

There was a smaller room there before, used for coffin storage, and had a smoke detector in it.

Alarm engineer came, disconnected the detector base, pulled out the cable back to the call point and put the EOL in the call point.

Now the new room has been built, although a little bigger floor area and height, the same engineer turns up to “put the detector back on”

He spent over an hour on the phone to his boss asking if this room actually needed a detector or not…. admitted to me that he didn’t really know the regulations…. And seemed to me like he was swerving the job.

10 to 12m of FP200, a handful of P clips and the old base and detector…

To my mind it’s just as much risk as a storage room. More electrical devices, chemicals… staff will be working in there for some time, not just in and out.

“Oh, it’s an install job now.” teeth sucking noises

You could have had it done the time you’ve been on that bloody phone.

On a related theme, my mate just died who invented the throat lozenge. There was no coffin at his funeral.

- Reaction score

- 17,150

A while ago, the guy that invented the Hokey Cokey died, and they couldn’t get him in a coffin.

They put the left leg in, the left leg out…..

They put the left leg in, the left leg out…..

- Reaction score

- 5,864

@littlespark Thought you were being a little disrespectful to the dead there, then realised you probably meant "garage".

- Reaction score

- 4,380

All accords what car was kept in the garage, some cars where garbage. (BL)

- Reaction score

- 17,150

Yes… garage, not garbage.@littlespark Thought you were being a little disrespectful to the dead there, then realised you probably meant "garage".

Where they keep the horses.

@!*#. Damnit

Hearses.

It is when the do the pelvic thrust, well that drives me insane.Hands on hips for fire alarm installers.

- Reaction score

- 17,150

First the Hokey Cokey, now the time warp…..

Commence new dance craze in 5….6….7….8

Commence new dance craze in 5….6….7….8

- Reaction score

- 6,893

I used to be work in this area and I agree! Though I did more fault finding and rectification than installing.

Several large firms used to sub out installations and getting a good job entirely depended on whether the subbies had high personal standards and were willing to go the extra mile while getting paid a sub-optimal rate for it. A rare few did this regardless, but needless to say this was the exception not the rule. The install usually stayed appalling for the first year until the service team went out for first annual inspection and testing, had a hissy fit, and then one of us would get the call to go and "tidy it up a bit" which often meant doing most of it again much to the irritation of the boss of the service side.

My suggestions that it would be better to keep an eye on the original install fell of deaf ears, and I eventually moved to a much smaller firm, a period I look back on with fondness as the guys were brilliant, teamwork at its best, and high standards.

I see them walk in to newly competed buildings, with almost everything done for them, and still leave the place in a mess. To be fair, fire alarm installers are still a few steps above the guys who do intruder alarms. They walk into the same new installation and start work on a spiders web.

- Reaction score

- 2,102

And that sheathed cable is connected to a metal clad FCU which is connected to the copper pipe so makes it an accessory point. 411.3.1.1 states this very clearly

If the copper pipe isn't connected to the fcu and isn't an extraneous conductive part and the cable is double insulated, then the pipe isn't an exposed conductive part and wouldn't require bonding.

- Reaction score

- 2,102

The few I have seen didn’t have any teethThe less said about fire alarm installers, the better.

Shortest route from A to B. Swing out under trunking lid. Notch conduit boxes. Just whatever gets the job done, tools packed up and on the road home at the earliest possible time.

Don't get me wrong; there are some good guys out there, but the good guys are few and far between. Most turn up on site swaggering like the fourth emergency service, suck air through their teeth and then turn out rougher work than most people would think possible.

- Reaction score

- 2,102

I get the same thought but mine involved kylie minogue.It is when the do the pelvic thrust, well that drives me insane.

But each to their own

- Reaction score

- 6,893

It's like the old Meat Loaf song - 4 out of 8 ain't bad,

- Reaction score

- 4,659

On the positive side, think of how low her gas bill will be this winter!Friend of mine said her new Hive thermostat wasn't working properly

Looks fine to me.!!!! But REALLY don’t like the Brown/Cream coloured role of Lino, to the left of photo.!Right ... Just been nudged to set this up by Paul.M and sounds a good idea following recent threads I've done in the Arms..

Rules....No Offensive material... edit if required before posting as this is the public arena.

Anything to do with the trade or in and around it ...H&S pic's welcome.

View attachment 28495

I've posted this a few times and this is at a mates house following a kitchen refirb several yrs ago.mg_smile:

View attachment 28495

Turn that rad OFF…!!Friend of mine said her new Hive thermostat wasn't working properly

View attachment 110860

Can anyone see why...

Plumber did the install apparently

I charge the client a full days ££££

- Reaction score

- 6,893

New way to connect a FCU. Done by - or at least under "supervision" of - a spark who was using NIC branded forms. Supplies this hand dryer.

Fancy junction box.

I've seen worse, much much worse !Newly added data points.

Went to test the cabling left behind by one tenant when they vacated an office, only found 2 pairs connected but on some it was 12&45, others it was 36&78 (or something like that), but also with pairs swapped so 36&78 might appear on 12&45 on the other end. Plus a few where there was nothing connected according to the tester.

Story was that the previous tenant (also a client of ours) had several offices, when they left, they had their electrician separate the networks so each was separate. No offence intended, but like previous criticism of plumbers and alarm installers, "a few" electricians really shouldn't be let loose with network cabling - especially if they aren't prepared to invest in at least the most basic of test equipment.

So, anyone like to guess what was wrong ?

One worked to the A standard and the other the B standard.I've seen worse, much much worse !

Went to test the cabling left behind by one tenant when they vacated an office, only found 2 pairs connected but on some it was 12&45, others it was 36&78 (or something like that), but also with pairs swapped so 36&78 might appear on 12&45 on the other end. Plus a few where there was nothing connected according to the tester.

Story was that the previous tenant (also a client of ours) had several offices, when they left, they had their electrician separate the networks so each was separate. No offence intended, but like previous criticism of plumbers and alarm installers, "a few" electricians really shouldn't be let loose with network cabling - especially if they aren't prepared to invest in at least the most basic of test equipment.

So, anyone like to guess what was wrong ?

Where's the output from the spur, or is it bunched in with the T&E'sNew way to connect a FCU. Done by - or at least under "supervision" of - a spark who was using NIC branded forms. Supplies this hand dryer.

Indeed, it's in with the T&Es. As suggested above, "fancy junction box". Cautionary tale: always do the safe isolation thing and test everything.Where's the output from the spur, or is it bunched in with the T&E's

- Reaction score

- 16,729

Where's the output from the spur, or is it bunched in with the T&E's

I think they've wired it in with the feeds, hence nicebutdim's comment.

More fun than that - mixing A and B would swap pairs butvstill leave 4 pairs connected. In this case, only 2 pairs were connected between any patch panel socket and wall socket.One worked to the A standard and the other the B standard.

Thise who've worked with network cabling for a while will know that the panels have different terminal layouts. This may or may not work ...

Some have the terminals like this :

45 12 36 78

Bl Or Gr Br

01

02

Bl Or Gr Br

45 12 36 78

i.e. all the terminals for port 1 are in a line on the top, with those for port 2 in a line at the bottom.

Some have tbe terminals like :

45 12 45 12

Bl Or Bl Or

1 2

Gr Br Gr Br

36 78 36 78

Needless to say, the clueless idiot didn't bother looking at the markings and used the wrong layout. So socket 1 had 2 pairs from port 1 and 2 pairs from port 2. Then socket 2 had the other 2 pairs from ports 1&2 ! And so it went, with the added bonus that none of the cables were numbered and he'd mixed a few of those up as well.

Basically had to pull all the cables off the panel, work out which was which (give the tone set an outing), and reterminate them.

On another occasion, the tenant took their cabinet and were supposed to leave the cabling. Something got lost in translation, as their lecky just chopped the bundle of cables - fortunately, leaving just enough length to re-use them (again, tone set job to work out which was which).

- Reaction score

- 22

American and British, it doesn't stand for those specifically but it's a good rule of thumb. Everyone use B for British across the board in the UK so there's never any major ---- ups.One worked to the A standard and the other the B standard.

- Reaction score

- 5,864

I'll remember that - didn't realise it was that simple.American and British, it doesn't stand for those specifically but it's a good rule of thumb. Everyone use B for British across the board.

Bought my first RJ45 crimper back in the summer to make up half a dozen cables. All worked first time, except one 40m cable, so I invested in a cheap cable tester recommended in a thread on here. Soon found the problem using that. Master was sequencing 1,2,3...8, while the slave was sequencing 8,7,6...1 - I'd crimped one of the plugs on upside down. Could make out which is was through the translucent plastic of the plug, so five minutes later and one scrap plug, all was good.

- Reaction score

- 2,102

I'll remember that - didn't realise it was that simple.

Bought my first RJ45 crimper back in the summer to make up half a dozen cables. All worked first time, except one 40m cable, so I invested in a cheap cable tester recommended in a thread on here. Soon found the problem using that. Master was sequencing 1,2,3...8, while the slave was sequencing 8,7,6...1 - I'd crimped one of the plugs on upside down. Could make out which is was through the translucent plastic of the plug, so five minutes later and one scrap plug, all was good.

I find this to be a decent tester for the price.

NF 488 Network Cable Tester / Poe Checker | eBay

Find many great new & used options and get the best deals for NF 488 Network Cable Tester / Poe Checker at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Also using through hole wiring plugs makes life easier

- Reaction score

- 5,864

Is that where you trim the cores to length after the plug is fitted?Also using through hole wiring plugs makes life easier

- Reaction score

- 16,729

Is that where you trim the cores to length after the plug is fitted?

Yes. Much easier.

You've reminded me of an "incident" from a good few years ago. My employer at the time managed a campus WAN for a science park - each office/unit was pre-wired with a couple of network points, and one was cabled back to a switch port. We could remotely provision internet access just by configuring the port and allocating them an IP address or range.... I'd crimped one of the plugs on upside down. Could make out which is was through the translucent plastic of the plug, so five minutes later and one scrap plug, all was good.

Unfortunately, wherever you put these sockets, it's going to be in the wrong place for someone - and sure enough, a business moved in but needed the internet connection to their server room the other side of the unit. So one 40m cable and a few lifted floor tiles later, internet provided where it was needed. Only it "didn't work".

We ended up on a 4 way call - me, the people who at the time managed the network for us, the customer's IT guy, and their external IT support. It turned out, the guy "knew" he needed a crossover cable so cut the plug off and fitted a new one wired as a crossover. - neither our switch, nor his firewall had auto MDI (most devices will automatically switch modes as needed these days so crossover cables are rarely needed, this was some time ago).

The customer's IT guy talked him through finding another crossover cable and an inline coupler. The customer said he'd found one and "it's yellow, is that OK ?" His IT guy responded as I'd have loved to ... "I don't f***in care what colour it is as long as it's crossover".

Needless to say, with the extra crossover in line, our "it's not working" service sprang into life. I managed to refrain from "I told you so" (or something to that effect).

- Reaction score

- 2,102

Strange that it didn't seem to trip either.

As I've mentioned previously we do a bit of work for insurance companies that put right council/housing association properties after fires/floods etc. (this one was a fire caused by a weed grow). What we usually find in a lot of council properties in our area is the kitchen (if its still there) has been upgraded recently with a new ring and cooker circuit and RCBO's installed in place of the non protected circuits but usually the original consumer unit remains, usually very badly done. this was todays example doing an EICR.

Only a little thing but it took me about two hours to rectify, all because they tried to cram a cooker switch into a 25mm box, couldn't get it back so trimmed the cables down as short as possible. Stuff like this wouldn't normally bother me but we get major grief of the council bods for the slightest thing we do wrong (it might be we put 0.4s in the disconnection box on the cert instead of 5s or fit a 230V 9V backup heat alarm instead of a lithium one) yet the actual dangerous stuff they are totally oblivious to and I come across it time after time.

Only a little thing but it took me about two hours to rectify, all because they tried to cram a cooker switch into a 25mm box, couldn't get it back so trimmed the cables down as short as possible. Stuff like this wouldn't normally bother me but we get major grief of the council bods for the slightest thing we do wrong (it might be we put 0.4s in the disconnection box on the cert instead of 5s or fit a 230V 9V backup heat alarm instead of a lithium one) yet the actual dangerous stuff they are totally oblivious to and I come across it time after time.

- Reaction score

- 6,893

Was reading a thread about repairing imperial MICC and remembered this abomination near me where someone has replaced a Coughtrie light with something of a different size:

View attachment 111124

They had to feel good standing back and looking at that upon completion.

lozarus

-

- Reaction score

- 326

Yes. Much easier.

Need to be careful with these. I chased down an issue at work recently where these had been used but a few hadn't been cut perfectly flush. Results in them not sitting square and breaks contact.

Also in damp environments they can occasionally get a bit fusty at the bare ends and again make poor contact.

In defence of the LV folk, i started in this trade - and there is an art to it - just like with mains. A caring LV installer will confirm that with enough practice and the right technique its possible to make a sound and easy crimp, first time with traditional RJ45s.

Indeed. By the time you've done a few hundred, or thousand, it gets easy. At a previous job, we used to get work experience kids from school - I'd show them how it's done, let them do their own (with assistance), and then they could take home their very own patch cable that they'd made. It went down well.... there is an art to it - just like with mains. A caring LV installer will confirm that with enough practice and the right technique its possible to make a sound and easy crimp, first time with traditional RJ45s.

Plus it was easier than explaining all the other stuff I did - without giving away too many secrets.

Really?Was reading a thread about repairing imperial MICC and remembered this abomination near me where someone has replaced a Coughtrie light with something of a different size:

View attachment 111124

Reply to Dodgy trade pictures for your amusement! - 1 Million Views! in the UK Electrical Forum area at ElectriciansForums.net

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

YOUR Unread Posts

-

What is it called IR testing?Funnily enough I managed to zap my self today walking about after forgetting to turn auto off 😂

- Latest: KungFuTurkeyLeg

-

replacing a dimmer light switch with a regular oneCan you use a wire nut on a single wire? Does it grip with only one conductor?

- Latest: Marvo

-

UK Electric combi boilerA Single Phase Combi is possible, but please observe the flow rate in the technical...

- Latest: mainline

This website was designed, optimised and is hosted by untold.media Operating under the name Untold Media since 2001.