While insisting on AFDD might seem like a good idea, in practice it is not necessarily so.

1) AFDD are not that good at stopping fires. They only add detection of an arc, and not overheating, and even the arc aspect is not that convincing (just search YouTube for John Ward doing some tests on AFDD). Also as I mentioned they do not stop fires from a simple poor connection or under-rated cable, nor would they stop fires from the likes of tuble dryers building up lint which as often classed as "electrical fires":

If they were a magic bullet to stopping fires, then why don't we see detailed analysis of what proportion of fires would be prevented?

2) They add a lot of cost. Sure that will no doubt drop in time, but today you could be looking at £2000 extra on the cost of a rewire or new CU. Now if you have paid off your mortgage and earn £50k/year that might not trouble you, but for the majority of folk that is going to make them think twice.

The unintended consequences of that are either poor electrical installation going unfixed, instead of being brought up to date with at least RCDs, or them going to some dodgy character a mate at the pub knows, and probably getting a far less safe job done (maybe with fake AFDD off eBay, etc, as well)

3) For a given budget, you would be better spending the extra AFDD money on a proper linked-up fire/smoke alarm. Why? Well because only around 12% of fires are due to the wiring that

might be protected by the AFDD but your smoke alarm should give to a chance to escape all of them:

Updated for 2023/24, the following fire statistics have been compiled to draw attention to the risks of house fires in the UK.

www.morganclark.co.uk

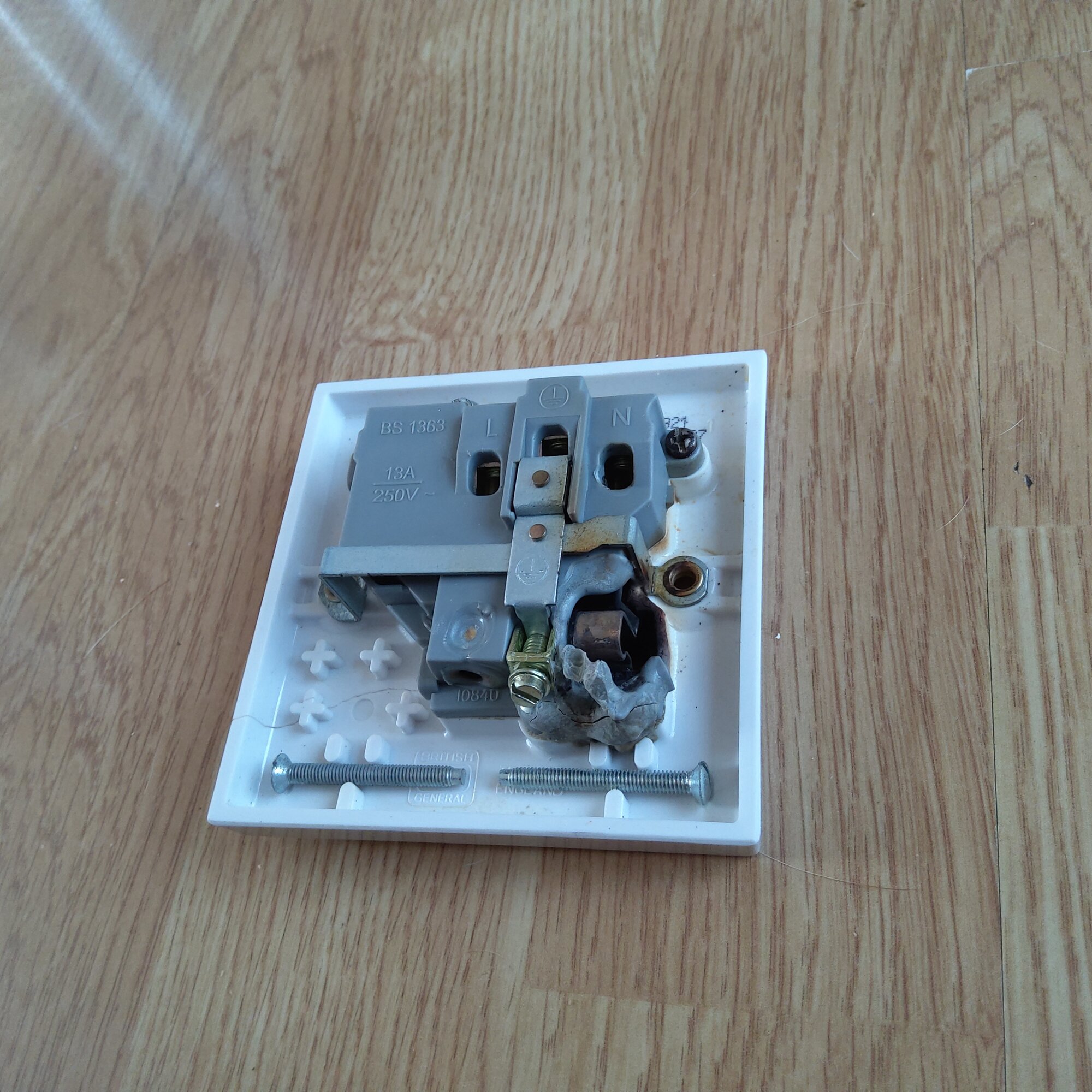

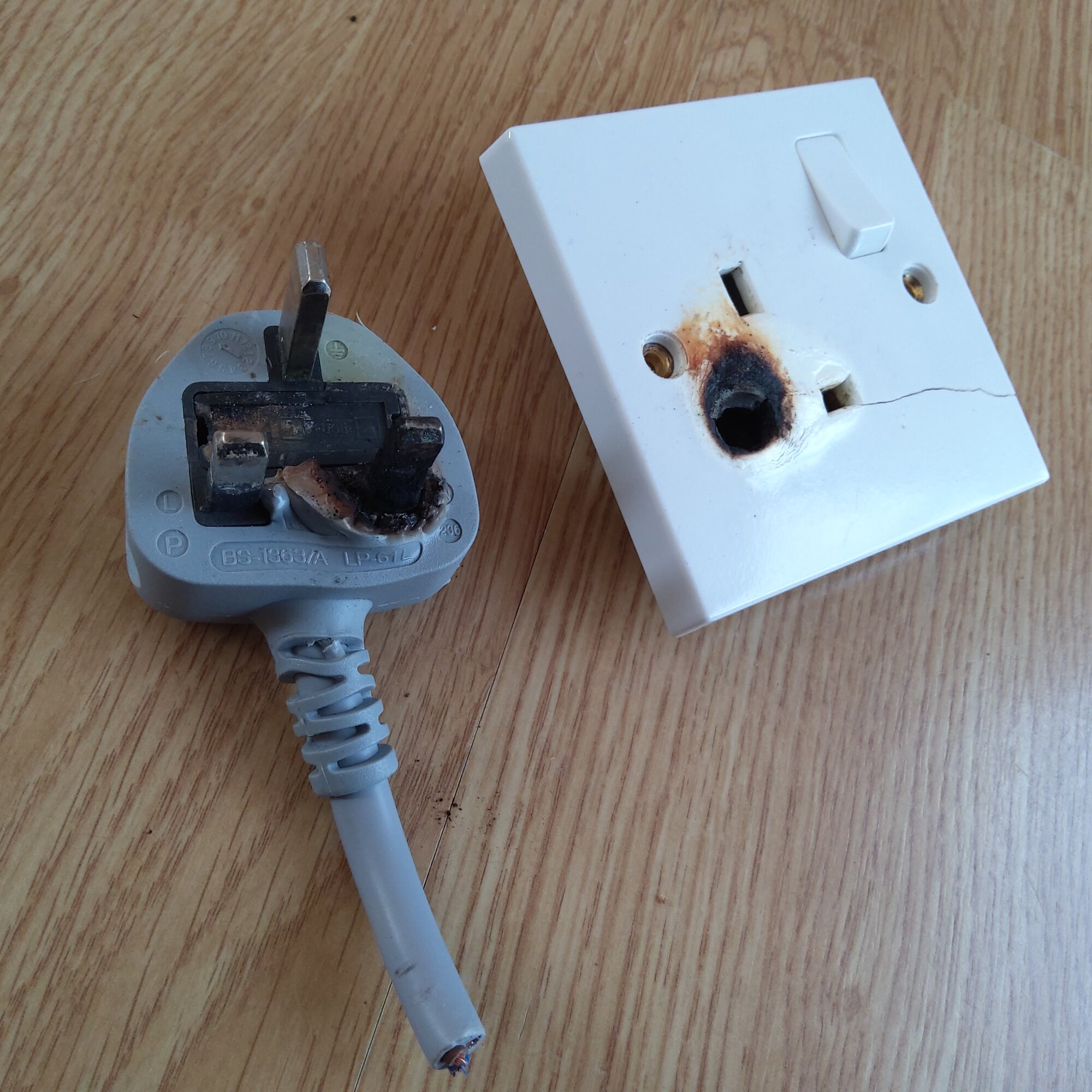

Overheated plug/socket combinations can be due to either the socket, which would be your electricians responsibility, or the appliance plug, which is another issue. To me "

wiring difficulties on the age and location of my house" sounds very suspicious, but without full details and someone interdependently looking at it I could not say any more.